Construction of a pattern for men's semi-fitted trousers. Patterns for men's trousers and description of sewing How to cut men's sports trousers

Sweatpants will always find their place in a man's wardrobe, even if he is far from sports. These pants are used as home wear or for going out into the countryside. Depending on their purpose, trousers are made from different materials. For example, thin knitted ones are suitable for home, for jogging in the cold season - lined with fleece, for outdoor activities - made of raincoat fabric or other water-repellent material.

There are many options for these trousers. You can find pants with stripes, with internal or patch pockets, with a zipper or elastic. There are single-layer products or with lining.

Model selection

Let's focus on the simplest option and sew sweatpants with elastic without pockets.

Sewing sweatpants with elastic is very simple. Even a novice seamstress can complete this task.

Sewing sweatpants with elastic is very simple. Even a novice seamstress can complete this task.

Materials and tools

We use thick knitted fabric as the main material. You will also need a belt cord and a thin elastic band.

Required tools:

- sewing machine with zigzag or overlock stitch;

- needles for knitted seams;

- pins;

- ruler;

- graph paper;

- tracing paper;

- tape measure;

- pencil;

Step-by-step construction of a pattern

We take several measurements of the figure:

- semi-circumference of the hips;

- length of the trouser leg from waist to floor;

- knee height (from waist to knee level);

- length of the leg along the inner surface;

- width of the bottom of the trouser leg.

We build a pattern for the front part:

- From the upper left corner we build a vertical line TN. On it, from the waist down, we set aside the height of the knee, put it so K; from bottom to top - the length of the trouser leg along the inner surface (I).

- From t. I set aside the line of the hips, put point B. We calculate the distance YB as follows: divide the measurement of the half-circumference of the hips by 10 and add 3 cm. We draw horizontal lines through all new points.

- From B we set aside the width of the front of the trousers and put point B 1. It is equal to half the hip circumference plus 1.5 cm. Through B 1, draw a vertical line up and down, forming T 1 and Z 1.

- We calculate the width of the step B 1 B 2: divide the half-circumference of the hips by 10 plus 1 cm. Draw the central vertical through B 3. B 3 = BB 2 /2. We mark K 1 and H 1 on it.

- From H 1 we put H 2 and H 3 at the same distance, which is equal to half the width of the lower part of the trouser leg minus half a centimeter.

- From H 2 and H 3 to the center we set aside 0.5 cm and from these points upward we draw inclined lines to points A and B 2, respectively.

- From the point of intersection of the inclined line with the knee line to the center, set aside 1 cm (K 2). From K 1 to the right we build a segment equal to K 1 K 2, put K 3.

- We build the middle line. From T 1 to the left we set aside 1 cm (T 2). From I 1 - up half the length of I 1 I 2 (A1). We connect point A 1 to Z 2.

- We connect T, T 2, B 1, I 2, H 3, H 2, K 2, I. We draw up the middle line using a pattern.

We build a pattern for the back part:

- We construct it based on the front pattern.

- We expand the bottom line by 1 cm on each side. We do the same with the knee line. We put points K 4, K 5, H 4, H 5.

- We put B 4, for this we set aside 2 cm from B.

- We set aside the width of the rear part from B4, set B 5. The length of straight line B 4 B 5 is half the hip circumference measurement plus 4 cm.

- We determine the width of the step B 5 B 6, it is equal to the measurement of the half-circumference of the hips divided by 5 plus 3 cm. From I upward we set aside 2 cm (A 2). Let's connect the segment A 2 B 5 and build a perpendicular to it from B 5.

- Draw an auxiliary line K 5 B 6. We set aside I 3, so that K 3 I 2 = K 5 I 3 - 0.5 cm.

- Draw the segment K 4 B 4 and extend it upward. We put point T 3 on it, so that the distance K 2 T is equal to K 4 T 3.

- We build an auxiliary line K 1 T 4, so that its length is equal to K 1 T 3 + 1.5 cm, while K 1 T 4 should pass in the middle of the segment B 3 B 5. We draw the middle line with a smooth curve.

- We connect the points T 4, T 3, B 4, K 4, H 4, H 5, Z 5.

We transfer the details of the front and rear parts onto tracing paper. Cut it out.

Cutting the material

ADVICE! To avoid shrinkage of the finished product, it is recommended that before you start cutting the material, you first wash and iron the fabric from the wrong side.

Fold the material right sides inward. We pin the pattern from tracing paper with safety pins, outline it with chalk, add 1.5 cm to the seam allowances on each side and 4 cm to the bottom seam allowances. We cut out the parts taking into account the allowances.

We cut out a belt with a length equal to the waist circumference according to patterns, 10 cm wide, taking into account allowances.

ATTENTION! When determining the waist circumference using patterns, do not forget to multiply the value for each part by 2.

Sewing stages

- We process the cuts with an overlock or zigzag stitch.

- We sew up the step, side and middle seams. After this, it is better to try on the product. If the pants fit well and do not pull anywhere, you can sew these seams on a sewing machine using a zigzag stitch with a fine screed width. The middle seam is made by inserting the right pant leg into the left one, face to face. Press the crotch and side seams, press the middle seam until it is rounded.

ATTENTION! When sewing knitted fabrics on a sewing machine, you should use a special needle for knitwear. It has a rounded tip, with which it does not pierce the material, but gently pushes the loops apart, preventing the appearance of hooks and arrows when wearing the product.

- We sew down the belt detail along the short side. Then, fold lengthwise with the wrong sides facing inward. At a distance of 1.5 cm from the fold, we lay a straight machine stitch along the front side. We make another similar line parallel to the first one at a distance of 1.5 cm from it in the direction of the cut.

REFERENCE! To get perfectly straight stitches, it is better to use a special sewing machine foot with a ruler.

- We connect the belt with the product, placing it on the front side of the trousers with the cut side up. We pin, aligning the back middle seam with the waist seam. We make a basting and sew a zigzag seam with a fine screed width. Iron the seam down.

- On the front of the belt, at an equal distance from the middle seam, we make two identical holes for the lace and elastic. We sew them by hand. Using a regular pin, insert the elastic into the belt, tie it and hide the edges of the elastic in the belt. We thread the decorative cord in the same way, bringing its ends out.

- We try on the pants and determine the hem line. We bend the bottom edge, lay a basting line, fold it a second time, and sew a basting line again. Let's iron. We make a straight machine seam at a distance of approximately 1.5 cm from the edge.

As an additional element, you can make a back patch pocket:

- To do this, we cut out a pocket detail, maybe even from a contrasting fabric.

- We bend all the edges inward. Iron them thoroughly. We stitch the top edge using a machine.

- Pin the pocket to the back of the trousers. Let's baste. We attach on three sides at a distance of 1–2 mm from the edge.

Men's sports trousers are ready.

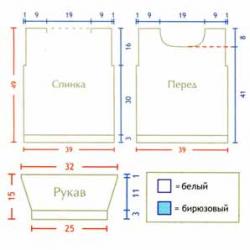

Opening a new topic “Creating patterns for men's clothing”. Let's go from simple to complex.

Let's start by creating a pattern for pajama pants. Using the same pattern, you can sew any lounge pants, Bermuda shorts or summer shorts.

Our men can also try their hand at sewing.

To do this we need three measurements.

For example, we use standard size 50 measurements, and you take measurements from the figure of the person for whom you are going to sew these pajamas.

Pants length db...................104 cm

Half waist circumference St.......42 cm

Half hip circumference Sat......50 cm

The amount of increase for a loose fit depends on the degree of desired fit to the figure, on the type, composition and properties of the fabric.

Pajamas are clothes that are designed to fit loosely enough to provide comfort first and foremost. Therefore, instead of a tight belt, we provide for processing the upper section of the trousers with a drawstring with an elastic band, which will allow you to adjust the tightness of the fit. The drawstring can be one-piece with the main parts of the trousers or cut off. This should be taken into account when constructing a pattern or directly during cutting. The main thing is not to forget about this.

CONSTRUCTION OF A PATTERN DRAWING FOR PAJAMA PANTS.

FRONT HALF OF PANTS.

In the upper left corner we draw a right angle and denote the vertex with the letter T.

From point T downwards we set aside the taken measurement of the length of the trousers. In our example, this is 104 cm, and you set aside your measurement and put point H. TN = Db = 104 cm. From point H to the right, draw a horizontal line of arbitrary length.

From point T down, set aside 1/2 of the half-circumference of the hips plus 3 cm and place point Z.

TY = Sat: 2 + 3cm = 50: 2 + 3 = 28cm. ATTENTION:

You substitute your hip half-circumference value into the formula and make your calculation.

From point I to the right, draw a horizontal line of arbitrary length.

From point H upward we set aside 1/2 of the distance YH plus 6 cm and place point K.

NK = YAN: 2 + 6cm = 76: 2 + 6 = 44cm.

You measure the YAN segment on your drawing and make a calculation.

From point K to the right, draw a horizontal line of arbitrary length.

Width of the front half.

From point I to the right, set aside 1/2 of the half-circumference of the hips plus 6 cm and place point I1.

RY1 = 1/2 Sat + 6 cm = 50: 2 + 6 = 31 cm.

From point H1 we lower the perpendicular to the bottom line and place point H1. The point of intersection with the knee line is designated by the letter K1.

From point T to the right, set aside 1/2 of the waist circumference plus 6 cm and place point T1.

TT1 = 1/2 St + 6 cm = 42: 2 + 6 = 27 cm.

And don’t forget to substitute your values into the formula.

From point T1 we lower the perpendicular to the line РЯ1 and denote the point of intersection with the horizontal line РА1 with the letter Р2.

From point T to the right, set aside 2 cm (for all sizes) and place point T2.

From point T1 we set aside 1 cm downwards (for all sizes) and place point T3.

From point H to the right, set aside 3 cm (for all sizes) and place point H2.

From point T down, set aside 18 cm (for all sizes) and place point B. This point determines the position of the hip line.

We draw up the side line. To do this, connect points T2, B, Z and H2.

From point Y2 upward we set aside 6 cm (for all sizes) and place point C. And again from point Y2 along the bisector of the angle upward to the right we set aside 2.5 - 3 cm (for all sizes) and place point C1.

We connect points C, C1 and R1 with a smooth line.

Thus, the middle cut of the front half of the trousers will pass from point T3, then through points C, C1 and R1.

Step-by-step cut of the front half.

Along the bottom line from point H1 to the left, set aside 3 cm (for all sizes), put point H3 and connect it with a straight line to point H1.

The segment H2H3 defines the bottom line of the front half.

This completes the construction of the front half of the pajama pants.

BACK HALF OF TROUSERS

We start constructing the back half of the trousers from a right angle in the upper right corner with the apex at point T4.

Down from point T4 we place the measurement for the length of the trousers. In our example, it is 104 cm, and you set aside your measurement and put point H4.

Т4Н4 = Db = 104 cm.

From point H4 to the left, draw a horizontal line of arbitrary length.

From point T4 to the left we set aside 1/2 the measurement of the half-circumference of the hips plus 6 cm and place point T5.

TT1 = 1/2 St + 6 cm = 42: 2 + 6 = 27 cm.

T4T5=1/2 Sat+6 cm= 50:2+6=31 cm.

From point T5 we lower the perpendicular to the bottom line and mark the intersection point with the letter H5. Seat height

as well as on the front half of the trousers, we determine it by calculation. From point T5 downwards we set aside 1/2 of the semicircle of the hips plus 3 cm and place point H3.

TT1 = 1/2 St + 6 cm = 42: 2 + 6 = 27 cm.

T5Y3=1/2 Sat+3 cm=50:2+3=28 cm.

We draw a horizontal line through point Y3 and mark the point of intersection with the vertical T4H4 with the letter Y4.

We divide the segment T4T5 in half, put point T6. From this point upward we draw a perpendicular 4 cm long (for all sizes) and place point T7.

Extend line T5T4 to the right and from point T7, using a compass, make a notch on it with a radius equal to 1/2 of the waist half-circumference plus 2 cm and place point T8.

See the picture below.

TT1 = 1/2 St + 6 cm = 42: 2 + 6 = 27 cm.

Т7Т8 = 1/2 St + 2 cm = 23 cm.

From point T8 through point T7 we draw a straight line, extending it to the left of point T7 by 5 cm (for all sizes) and place point T9.

Middle cut of the back half of the trousers.

We connect points T9 and R3 with a straight line.

From point R3 up along the same line we lay off 1/3 of the segment R3T9 and place point C2.

From point R3, continuing the horizontal line to the left, set aside 1/4 of the segment R3R4 and place point R5.

R3R5 = 1/4 R3R4 = 31: 4 = 7.8 cm.

You substitute your values into the formula.

We divide the segment Y3Y5 in half and put 1 cm down at a right angle (for all sizes) and put point Y6.

We draw up the middle line of the back half of the trousers by connecting points T9, C3, R3, R6 and R5.

Look at the picture below.

From point H4 upward we set aside 1/2 of the distance R4H4 plus 6 cm and place point K2.

From point K2 to the left we draw a horizontal line.

The point of intersection with the vertical T5H5 is designated by the letter K3.

From point H5 to the left, along the continuation of the bottom line, set aside 1 cm and place point H6.

From point K3 to the left, on the continuation of the knee line, set aside 4 cm and place point K4.

K3K4 =4 cm (for all sizes).

We connect points R5 and K4 with a straight line and divide this segment in half. We denote the division point with the letter B and from it to the right at a right angle we set aside 0.5 cm and place point B1.

We make a step-by-step cut of the back half of the trousers, connecting points H5, B1, K4 and H6.

Look at the picture below.

From point H4 to the left we set aside 6 cm and place point H7.

By connecting points T8 and H7, we form the side cut of the back half of the trousers.

The segment H6H7 defines the bottom line of the back half of the trousers.

This completes the construction of the pattern for men's pajama trousers.

The resulting drawing can be used as a basis for further modeling. Using simple techniques, you can use it to create a wide variety of styles of trousers, Bermuda shorts, shorts, etc.

IMPORTANT! Don't forget to make a double allowance for the elastic at the top edge. The size of the allowance will depend on the width of the elastic and the number of rows. You can cut the belt separately, sew the required number of lines, insert an elastic band and sew the finished belt to the trousers. The choice is always yours, and options are always possible!Cutting details

In our article, all figures are given as an example only. You can change any and use the values that suit your case. For example, by increasing the allowance for a loose fit, we get looser trousers and vice versa.

This is just one of the variety of options for constructing men's trousers that exist and which we will master.

We will tell you how to create a pattern for the pajama top in the next article.

Follow the site news and you will always be up to date.

The one who walks will master the road! I wish you good speed!

Don't forget to add it to your bookmarks. The bookmark buttons are below.

The rights to this article belong exclusively to the author. Full or partial use of the materials of this article in electronic publications on the Internet is possible only if the following conditions are met:

Information about the author must be preserved. In the title or at the end of the published reprint the source must be indicated: www.site, the Internet resource "Sewing Crafts Master" with a direct, active, visible to the user, not blocked from indexing by search engines hyperlink to this article.

Republication of texts in newspapers, magazines or other replication outside the Internet is possible only with the written consent of the author.

In the comments to previous entries, readers have repeatedly asked to publish an article with patterns for men's clothing. Finally, I’m keeping my promise and sharing free patterns of two trouser models. You can download them under the sewing description.

Pattern for men's trousers with a classic cut

This option is well suited for both office work and everyday wear. It all depends on what fabric you choose. Material consumption is indicated for sizes 48, 50, 52 and 54. Length along the side seam from the waist line: 112.5 (114-115.5-117) cm

What you will need:

- 1.75 (1.80-1.85-1.90) m gabardine width. 150 cm

- 35 cm (size 48/50), 40 cm (size 52/54) viscose lining in tone, wide. — 140 cm

- 55 cm cotton fabric (lining) in tone, width. — 140 cm

- 15 cm spacer adhesive material wide 140 cm

- 1.30 m matching bias tape

- 1 tone-on-tone zipper - 11 cm

- 2 buttons, 15 mm in diameter.

Pattern details for men's trousers

Plan for gluing pattern sheets

Copy the parts patterns. Draw parts E, F in the form of rectangles. For the lining, use the pattern of part 12, connected to part B, up to the marking line (approximately the knee line).

- REAR HALF OF TROUSERS 11+11A

- FRONT HALF OF TROUSERS 12+12A

- RIGHT SIDE OF THE CLASP 13

- BELT 14

- BARREL + POCKET LINING 15

- BACK POCKET LINING 16 = CUTTING OUT TO TURN OUT, ALIGNING THE FOLD OF THE TRAKING WITH THE BOTTOM LINE

- CUT LEFT SIDE OF CLASP A = COPY PART 12 FROM THE PATTERN

- BARREL OF THE FRONT HALF OF PANTS B = COPY PART 15 FROM THE PATTERN

- FRONT POCKET TURNING C = COPY PART 15 FROM THE PATTERN

- BACK POCKET VALVE D = COPY PART 16 FROM PATTERN

- BACK POCKET LEATHER E = 13X5 CM

- Belt Belts F = 57X2 CM

Layout plan

Lay out the patterns of the parts on the folded fabric. Place parts 13, A and F in a spread, see diagrams. Lay out the indicated patterns on a folded cotton cloth. Place part 13 on the canvas in a spread. On the folded viscose lining, lay out the pattern of part 12 (in the transverse direction), as shown in the diagram, aligning the lower cut of the part with the edge. Lay out parts 14 and E on the folded interlining material. Cut out the parts with an allowance of 1 cm. Add 5 cm to the hem of the bottom.

How to sew men's trousers

Duplicate the adhesive spacer. material of the specified parts.

Finish the darts on the back halves of the trousers.

On each back half of the trousers, make a welt pocket with a leaf with set-in ends: pin the inside along the pocket markings. back pocket lining side down. Iron the leaf along the wrong side. side inward. Sew it along the markings to the main part (right sides), directing the leaf with the fold down. Stitch the face valance on the opposite side of the pocket markings. side down so that between the lines there is a gap equal to the width of the leaflet in its finished form. Cut the main piece and the lining with diagonal notches to the ends of the stitches, fold the leaf upward, and the valance to the wrong side. side. Zigzag stitch the edges of the leaves onto the pocket lining. Fold back the lining, placing it over the valance. Straighten the valance and, following the markings, stitch its lower edge onto the pocket lining in a zigzag pattern. Attach the lining to the valance stitching seam. Secure the ends of the pocket by stitching along the base of the seam allowance corners. Sew the edges of the pocket lining. Baste the back pocket lining. Tack the ends of the pockets from the faces. sides of the main part.

Finish the front pockets: first sew a zigzag stitch and then a straight stitch on the flange (with the wrong side down) on the front. side of the barrel/lining. Likewise, stitch the facing of the front pocket onto the side/lining of the pocket. Finish the pocket as described in the Sewing Guide, sewing a finishing stitch along the edge, by hand, using small stitches.

Baste the front halves of the trousers onto the lining of the front halves of the trousers so that the lining does not pull in the main parts. Overcast the sections of the main piece, joining them together with the lining using overcasting stitches.

Sew the side and crotch sections of the trousers. Press the seams.

Fold the trouser halves together. sides inward, align their top edges, crotch seams and, stepping back approximately 8 cm from these edges, sew the middle edges to the fastener.

Fold the sill and sill backing together and grind the outer edges. Trim seam allowances to 5mm. On the front halves. trousers, sew a fastener with a hem on the men's side.

Process six belt loops. Baste the belt loops, placing them outward. sides down, onto the top cut of the product. Topstitch the belt loops, sewing seams at intervals of 2 cm from the top edge.

Trim, adding 1 cm to the seam allowance, the left side of the waistband at the front edge according to the markings. Edge the longitudinal internal sections of each part of the waistband with bias tape. Fold the waistband pieces in half lengthwise and stitch the ends. Trim the seam allowances to 5 mm, turn the parts of the belt right side out. side, straighten the ends and iron the pieces along the middle.

Sew the waistband pieces from the faces. sides of the trouser halves. Press the seams onto the waistband. Stitch the middle edges of the trousers (in the open area) and the back edges. sections of belt parts. Press the seam to a length of approximately 15-20 cm. Stitch the longitudinal edge of the inner side of the waistband into a stitching seam.

Fold the cross sections of the belt loops inward and sew the folds to the top edge of the belt.

Press the hem of the trousers to the wrong side. side and sew with hidden stitches.

Sew the loops along the markings on the slope and on the left end of the belt. Sew the buttons according to the eyelets.

Pattern for men's casual trousers

This model is in many ways similar to the previous one. The pattern in the document is located horizontally; when printing, it is recommended to select the “Poster” function and set the scale to 100% (see screenshot below).

You will need:

- main fabric for trousers;

- cotton fabric for burlap pockets;

- 1 m of lining fabric;

Agree, it will be very great if your son, brother, husband or father receives as a gift wonderful trousers, sewn with your hands with love. These trousers will fit perfectly on your figure and meet all requirements, since you can choose the fabric and other details to your liking. All that remains is to find out how to sew men's trousers so that they have a neat and elegant look. This is exactly what the article will discuss. I would like to immediately note that, unlike women's trousers, men's trousers have a number of exceptional features. The preservation of a beautiful and neat appearance by classic trousers for a long time is associated precisely with these tailoring features. Trousers for men should be durable and, at the same time, elegant, which is why it is so important to pay special attention to detail when sewing.

Sewing men's trousers with your own hands - work procedure

Sewing any clothing begins with drawing a drawing (pattern). You can cut the trousers yourself or use ready-made patterns.

Important! Using the finished pattern, be sure to check the coincidence of the drawing with the control lines of the waist, bottom, knee, hip and step.

In addition to creating a pattern, the technology of sewing men's trousers involves the following additional operations:

- Cutting out the lining - for the classic model.

- Arrow design.

- Processing of side pockets.

- Finishing the top edge with a stitched belt on a grosgrain ribbon.

- Processing the codpiece.

- Processing the bottom of the trousers.

Let us dwell in detail on each of the above sewing procedures.

Rules for cutting trousers, taking into account the model, size and fabric pattern

Initially, to sew men's trousers, you need to correctly calculate the fabric. Here are the recommendations:

- Standard men's trousers can be cut from 120-130 cm of fabric with a width of 150 cm. This fabric consumption can be considered the norm for small sizes (up to 44 inclusive).

- For trousers with a volume of more than 115 cm, material consumption increases to 1.5-2 m.

- For the cut of loose-fitting trousers, the rate of fabric consumption can double, and then 2.5-2.6 m of fabric will be required.

Important! To accurately calculate the required amount of fabric, mark the width of the fabric 150 cm on the floor and lay out the patterns. It is only important to fit the patterns in width, taking into account the cuts of the fabric edges and allowances. Do not forget about the allowances along the waist (1.5-2 cm) and bottom (4-6 cm). All other parts of the product will be placed in the resulting lunges.

A few words about loose fit

Loose-fitting trousers differ from other models in that no matter how hard you try to fit the pattern pieces into 1.5 m of length, nothing will work. Therefore, we recommend that you immediately buy two lengths, taking into account all the allowances, and then you can freely place both parts of the product pattern on one side (along the edge). To cut out the waistband and other details, use the remaining large lunge folded in half.

Making a layout on the fabric

To correctly cut fabric for trousers, use the following tips:

- Lay out the patterns on the fabric from the wrong side.

- To create a pattern, you need to take the following measurements:

- Half waist.

- Half hip circumference.

- Half knee circumference.

- Seat height.

- The length of the trousers is to the knee.

- Pants side length.

Important! Based on these measurements, a drawing of the pattern of the front and back halves of the trousers is constructed. If you use ready-made patterns, then check the main lines using the measurements taken, change or upgrade the drawing to suit your model.

- Apply patterns to the fabric with chalk or a thin piece of soap. You can use a pencil on light-colored fabrics, but the lines should be thin and almost invisible.

- Before applying the pattern, fold the fabric in half with the right side inward, and pin the edge together so that the fabric does not move during work (chalking and cutting). If the pattern of the fabric is checkered or striped, then combine it along the edges (transverse). Pin the edge together.

- On fabrics with a one-sided pattern or pile fabrics with brushed or asymmetrical checks, place the patterns in one direction.

- Cut pile fabrics so that the pile on the product lies from top to bottom.

- Calculate the amount of seam allowances depending on the type of material and the method of processing the cuts. On loose fabrics, increase seam allowances by 0.5-1 cm. Trim off excess material when overcasting.

- Before proceeding directly to cutting, steam the fabric from the wrong side. In this case, it is necessary to take into account the type of fabric, since shrinkage is different for each material.

- Lay out the pieces of both halves of the trousers so that the grain runs along the ironing line. To do this, measure the distance from the edge of the fabric to the ironing line in several places on the pattern. Align these points using a chalk line. This way you will transfer the ironing line onto the fabric.

- Once the cutting is complete, mark all the guide lines with slip stitches and iron the hemming line.

- At the final stage of cutting the product, baste and stitch the darts on the back half and at the waist. After this, perform a wet heat treatment and proceed directly to sewing the trousers.

Cutting out the lining for trousers

One of the main differences between the classic trouser model is the presence of lining on the front halves. The lining protects the product from “extended knees” while working at the table. The lining is cut out according to the shape of the front parts of the trousers. The length of the lining should be just below the knee.

After cutting out the lining, proceed to connecting the front and back parts of the trousers:

- Connect the lining to the front and back halves at the same time.

- Finish the bottom edges of the lining with an overlocker.

- Baste the trousers and prepare them for the first fitting, at which you determine the width and length of the trousers, the height of the trousers at the waist level, the entry line into the side pocket, and eliminate fit defects.

Design of creases on trousers

Make all changes after the first fitting and adjust the trousers: sew the seams and press them (except for the middle seam).

To create creases on your trousers, proceed as follows:

- Fold each leg individually so that the crotch seam matches the side seam.

- Pin the fabric.

- Iron with an iron (through a piece of cotton fabric) in the centers to obtain even arrows.

Processing side pockets

Men like to store a variety of things in their pockets - keys, phone, money, credit cards, so the pockets should be quite durable and moderately deep. The fabric for the burlap pocket should be dense. Typically, thick twill is chosen for this purpose to match the color of the trousers (or contrasting shades, depending on the model).

To design side pockets, you need to do the following:

- Prepare burlap for pockets.

- Finish the lower parts of the burlap with a valance.

- Process the top of the burlap.

We will tell you about all the details of pocket processing below:

- The burlap consists of two parts per pocket - lower and upper. The depth of the burlap is equal to the length of the brush + additional margin for freedom of movement of the brush. In order to cut out the details of the burlap, place your hand on the paper (fabric) and trace along the contour. Depending on your wishes, the pocket can be made of any shape and size.

- There should be two parts located in mirror image for one pocket.

Important! When cutting parts, do not forget to add allowances at the bottom of the burlap (1-1.5 cm).

To process the bottom of the burlap with a valance, proceed as follows:

- Cut the valance along the warp thread from the same fabric as the trousers. The valance should not be too small, but not too large, so that when processing the pocket the burlap itself is not visible. One side of the valance should be decorated with a smooth line, repeating the angle on the trousers in the area where the pocket is located.

- Overcast the rounded edge of the valance.

- Sew the valance onto the burlap piece.

The second piece of burlap must be connected to the trousers along the side and top seams, having previously supported the side seam from above. Proceed this way:

- Align the corner of the burlap with the top corner of the trousers along the side seam and connect along the marked line of the pocket entry.

- Cut the resulting allowance on the burlap to 1-1.5 cm.

- Fold back the burlap and stitch the top corner of the trouser leg onto it. The burlap allowance should be on the inside.

- Fold the burlap inside the trouser leg exactly along the line of the entrance to the pocket.

- Secure the entrance to the pocket with an iron.

- Secure the pocket entry line on the front side with a finishing stitch (0.5 cm from the fold).

- Machine stitch the top and bottom pieces of the burlap together, matching all the cuts.

- Smoothly shape the corner of the burlap. Process the cuts using an overlocker.

- Join the side seams together with the burlap.

- After processing the pockets, connect the trouser legs along the middle seam and stitch them with a double stitch for strength.

Important! To keep the entrance to the pocket firmly, place transverse machine fastenings along the pocket - near the side seam and the top edge of the trousers.

Codpiece processing

The fastener in men's trousers is processed in the same way as in ordinary ones, one feature is the codpiece. The usual fastener treatment involves a codpiece made from the same fabric as the trousers. In the classic version, this part consists of two parts, made in this way:

- 1 part is cut out from the main material (trouser) in one layer without folding. The edge of the codpiece must be overcast.

- The 2nd part of the part is cut out of lining fabric in two layers and is 15-18 cm longer. At the end, the codpiece should be slightly narrowed.

To sew men's trousers with the correct fit, connect both parts of the piece together in a straight line. Both parts are processed in the same way as in ordinary trousers. The only exception is the elongated part of the codpiece, since it needs to be edged around the middle seam, secured in several places with machine rivets.

The proposed construction was carried out using the unified TsOTSL method.

Initial data

To construct a drawing of the basis of men's trousers, you need to know the measurements of the figure and the additions to the main measurements:

S t- half waist circumference;

C b- semi-circumference of the hips;

D tk- distance from the waist line to the knee line;

D b- length trousers;

Sh n- the width of the trousers along the bottom line - is selected based on the customer’s wishes or according to the fashion trend;

Sh k- the width of the trousers at the knee level - is selected based on the customer’s wishes or according to the fashion trend (it is not necessary to know this value for construction);

Increase amounts P t And P b we select, according to the desired silhouette, from the table presented.

Constructing a basic drawing grid

The construction of a design drawing for men's trousers begins with the construction of a basic mesh (see figure on the left).

We draw a vertical line with its vertex at point T 0. From point T 0 down we lay off the segments that determine the position:

bottom line T 0 H 0 = D b;

knee lines T 0 K 0 = D tk;

seat height lines T 0 I 1 = 0.5* C b- 1...2 cm, where 1..2 is the free member, while the larger value of the free member is taken when constructing trousers for a full figure.

Using this formula, the seat height is determined for figures with a height of 176 cm; for larger or smaller heights, this value increases or decreases by 0.7 cm, respectively.

From the point I 1 upward, lay the segment I 1 B 1, which determines the position of the hip line:

I 1 B 1 = 1/3 T 0 I 1.

From point T 0 downwards lay the segment T 0 T 01:

T 0 T 01 = 0.1*( C b - S t).

Through points T 01, B 1, I 1, K 0 and H 0, horizontal lines are drawn.

The width of the front part of the trousers along the hip line is determined by the segment B 1 B 2:

B 1 B 2 = 0.5*( C b + P b).

A vertical is drawn through point B 2, at the intersection of which with the horizontal T 01 one obtains point T 2, and with the horizontal I 1 - point I 2.

Widening the front along the hip line

B 2 B 21 = 0.5...0.7 cm.

The front step width is calculated using the formula

I 2 I 3 = 0.1*( C b + P b).

If the increase P b large (5...7 cm), then

I 2 I 3 = 0.1*( C b + P b) - 0.5...0.7 cm.

The fold line of the trousers is located in the middle of the segment I 1 I 3, i.e. width of the front part of the trousers along the seat height line:

I 1 I = IA 3 = I 1 I 3 /2.

A vertical line is drawn through point I and when it intersects with the basic horizontal lines, points T, B, K, and H are obtained.

The width of the finished trousers along the bottom line is determined based on the customer’s wishes or according to the fashion trend. The width of the trousers along the bottom line of the front part is traditionally, according to the visual perception of the location of the side seam of the trousers, less than the width of the back part by 4 cm, i.e.

H 1 H 2 = Sh n- 2 cm.

Width of trousers along the bottom line of the front part in the drawing

НН 1 = НН 2 = Н 1 Н 2 /2.

Width of trousers along the hemline of the back in the drawing

NN 3 = NN 4 = NN 1 + 2 cm.

The position of the lateral edge of the rear part on the hip line is determined by the segment B 1 B 3:

B 1 B 3 = 0.1*( C b + P b) - 2 cm.

Width of the back of the trousers along the hips:

B 3 B 4 = ( C b + P b) - B 1 B 21 .

From point B 3 with radius B 3 B 4 draw an arc on which a segment B 4 B 5 is laid out, which determines the balance of the trousers:

B 4 B 5 = 0.05*( C b+ T 0 I 1) - 0.3...0.5 cm for a typical figure;

B 4 B 5 = 0.05*( C b+ T 0 I 1) + 0.5 cm for stooped figures and figures with convex buttocks;

B 4 B 5 = 0.05*( C b+ T 0 I 1) - 1 cm for curved figures and figures with flat buttocks.

Auxiliary point I 21 is needed to determine the position of the midline of the back of the trousers:

I 2 I 21 = (0.03...0.05) C b.

A larger coefficient is taken for products with larger figures.

Points I 21 and B 5 are connected by a straight line, continue it upward and lay off the segment B 5 T 5:

B 5 T 5 = B 4 T 2.

Point T 5 is the top of the midline of the back of the trousers.

Constructing the front of men's trousers

In the picture on the left you see a drawing of the front and back of men's trousers.

(To view an enlarged drawing in a separate window, click on the drawing with the mouse).

To construct the middle line, find auxiliary point 1. From point I 2 on the bisector of angle B 2 I 2 I 3 lay the segment I 2 1:

I 2 1 = 0.4*I 2 B 2.

The middle line is drawn through points T 2, B 21, 1, I 3.

Calculate the width of the front of the trousers along the waist line:

T 2 T 4 = 0.5*( S t +

P t) + in 1 + s,

where in 1 - tuck solution equal to 2...2.5 cm; c - fold depth equal to 3...5 cm.

The segment T 2 T 4 is laid on a straight line connecting points T 2 and T 0. Usually, for figures with a difference in the half-girth of the hips and waist, which is in the range of 4...10 cm, either a fold or a dart is provided; for more than 10 cm, both a fold and a dart are provided. In this case, the determining moment is the position of point T 4 relative to point T 0. The segment T 4 T 0 should not exceed 1 cm. For products for figures with increased protrusion of the abdomen, the midline and waist line are drawn slightly differently. From point T 2 upward, lay the segment T 2 T 3 - the rise of the waist line:

T 2 T 3 = 0.5*( S t+ 8 cm - C b).

From point T 3 to the right, a segment T 3 T 31 is laid horizontally - the displacement of the top of the midline:

T 3 T 31 = 0.4*T 2 T 3.

In this case, the middle line is drawn through points T 31, B 21, 1, I 3, and the waist line is drawn through points T 31 (T 2) and T 4, first horizontally at a distance of 1/3 of the width of the front part, and then along a smooth curve to point T4.

If the finished width of the trousers at knee level is known (at the customer’s request) Sh k, then from point K to the right and left the segments KK 1 and KK 2 are plotted:

CC 1 = CC 2 = ( Sh k- 2 cm)/2.

If this width is unknown, then from the point of intersection of the horizontal line drawn through the point K with the straight line I 1 H 1, a segment K 3 K 1 is laid off:

K 3 K 1 = 1...1.5 cm.

Moreover, the smaller the width of the trousers at the bottom, the greater the value of K 3 K 1. Next, from point K to the right, a segment equal to KK 2 is laid horizontally:

CC 2 = CC 1.

The step edge line is drawn through points H 2 and K 2 in a straight line, through points K 2 and I 3 - along a smooth concave line.

The side edge line is drawn through points H 1 and K 1 in a straight line, and then along smooth concave (K 1 and R 1) and convex (R 1, B 1, T 4) curves.

Raising the middle of the bottom NN 5:

NN 5 = 0...1 cm.

As the width of the bottom increases, the value of HH 5 decreases.

The bottom line is drawn in a smooth curve through points H 1, H 5, H 2.

Constructing the back of men's trousers

The rear step width along the seat height line is laid to the right from point I 21:

I 21 I 5 = 0.25*( C b + P b) - 1.5 cm.

To construct the middle line, find auxiliary points I 32, 2:

I 3 I 32 = 1 cm.

The segment I 3 I 32 is laid down along the line I 3 K 2:

I 21 2 = 2...3 cm.

The segment I 21 2 is laid up and to the right along the bisector of angle B 4 I 21 I 3.

The width along the knee line is determined by setting aside the segments KK 4 and KK 5 to the right and left of point K:

CC 4 = CC 5 = CC 1 + 2 cm.

Connect the straight points I 5 and K 4, the middle of the segment is designated by point 3. From point 3, line segment 3-4 is laid perpendicular to the straight line K 4 I 5:

3-4 = 1...1.5 cm.

The top of the step edge of the rear part is determined by setting aside the segment H 4 K 4 I 6:

N 4 K 4 I 6 = N 2 K 2 I 3 - 0.5...1 cm.

where 0.5...1 cm is the amount of tension on the pitch edge line.

The step edge line is drawn through points H 4 and K 4 in a straight line, through points K 4, 4, I 6 - along a smooth concave curve.

The middle line is drawn through points T 5, B 5, 2, I 32, I 6.

Back waist width:

T 5 T 7 = 0.5*( S t +

P t) + in 2,

where in 2 is the solution of the back dart (or two darts), equal to 2...4 cm. The solution depends on the degree of protrusion of the buttocks.

The segment T 5 T 7 is laid from point T 5 to the intersection with the horizontal line drawn through point T 0. The side edge line is drawn through points H 3 and K 5 in a straight line, through points K 5, B 3, T 7 - along a smooth curve.

The line of the side edge of the back is aligned with the line of the side edge of the front of the trousers:

N 3 K 3 B 3 T 71 = N 1 K 1 B 1 T 4.

The waist line is drawn through points T 71 and T 5.

A prerequisite is that at point T 5 the waist line forms a right angle with the midline.

Rear mid-bottom drop

NN 6 = 0.5...1 cm.

As in the front of the trousers, as the width of the trousers at the bottom increases, the value of HH 6 decreases. The bottom line is drawn through points H 3, H 6, H 4.

Position of darts and pockets

On the front of the trousers, the dart at the waist line is usually located along the fold line, its length does not exceed 1/3 of the seat height (segment T 0 I 01). The fold is usually placed to the left of the fold line.

The front pocket line can be placed in the side seam, obliquely, horizontally and vertically. The most common pocket solution is an inclined pocket with a cutting side. The upper end of the pocket is placed to the right of point T 4 at a distance of 3.5...4 cm. From this point on the line of the side edge, a notch is made with a radius equal to the length of the entrance to the pocket.

The length of the pocket entrance for sizes (based on chest girth) 88-96 will be 16 cm, for sizes (based on chest girth) 100-104 - 17 cm, for sizes (based on chest girth) 112-128 - 18 cm.

Horizontal pockets on both the front and back are built parallel to the waist line at a distance of 6...7.5 cm from it.

The end of the pocket facing the side edge is placed at a distance of 4...5 cm from it.

The length of the pocket entrance is equal for sizes (chest circumference) 88-108: 14 cm; 112-128: 15.5 cm.

One or two darts are built on the back of the trousers. The middle lines of the darts are placed perpendicular to the line of entry into the pocket.

You can read more about designing different types of pockets in men's trousers.

Checking the quality of the completed drawing

To check the correctness of the drawing of the design of men's trousers, perform the following work:

1) measure the front and back of the trousers along the waist line, hip line, knee and hem lines, the length of the trousers and compare the measurement results with the specified values. I check the calculation and height of the seat;

2) make sure that the lengths of the step and side lines of the front of the trousers correspond to the back of the trousers;

3) check whether the front and back parts match along the side line at the level of the waist and bottom lines, along the step line at the level of the seat height and bottom lines; two anterior parts along the midline; two posterior parts along the midline;

4) check whether the waist line is constructed and shaped correctly with closed darts and folds.